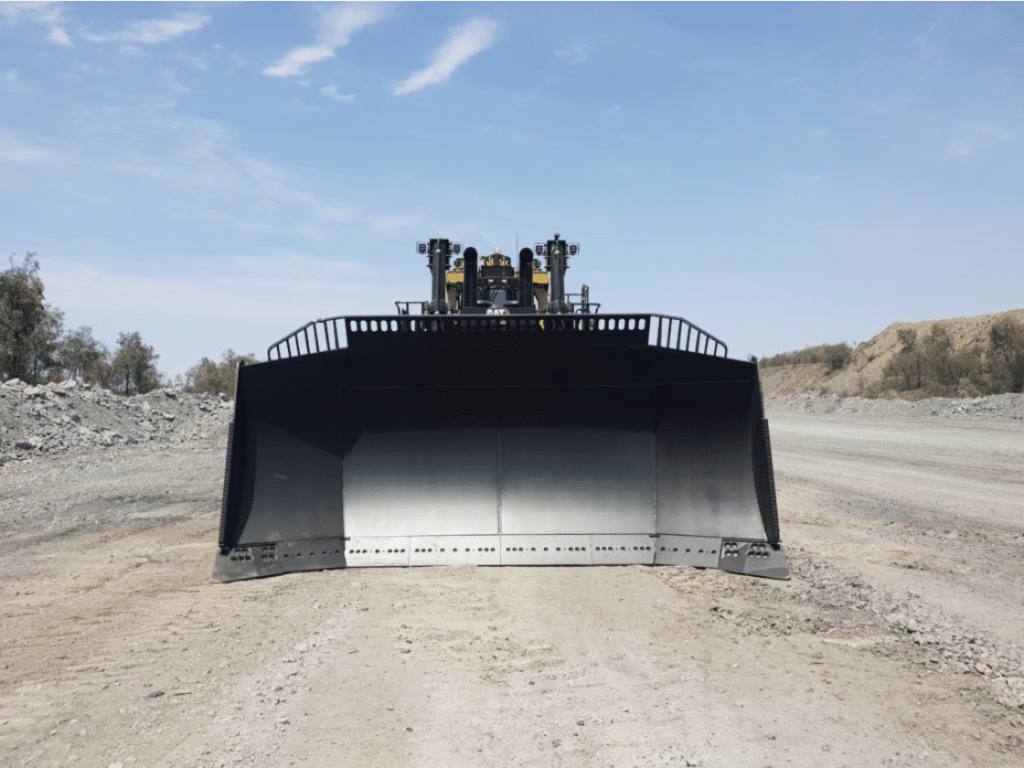

The mining industry is under increasing pressure to decarbonise, and one of the biggest levers we can pull is the materials we use, starting with steel. Right now, grader blades and other GET (ground engaging tools) are primarily made from virgin steel, but what if manufacturers could shift to using more recycled content?

Steel production is responsible for about 8% of global CO₂ (source: worldsteel.org) largely due to the reliance on blast furnaces. The good news is electric arc furnaces (EAF) that use scrap steel generate significantly lower emissions, but the bad news is that high-strength alloy steels (like the ones used in grader blades) currently rely on virgin iron ore.

If we were able to switch to EAFs studies have shown that up to 75% less carbon dioxide per ton of steel would be produced. This would be a game changer in terms of the environmental impact. When combined with a longer wear life product, recycled materials and a more efficient furnace the impact would be a huge help to making a real impact to the mining industry and the decarbonisation movement.

Unfortunately, switching to a more environmentally friendly solution isn’t without its challenges. Here are a few of the roadblocks that must be overcome before we can make the change a reality.

- Material Quality – Scrap steel often has impurities that make it unsuitable for heavy-duty wear applications.

- Technology Limitations – Existing steel recycling methods struggle to achieve the same strength as virgin materials.

- Cost & Supply Chain – High-grade recycled steel is still limited, and cost factors can make it less attractive.

But if these barriers can be overcome, the potential is massive. Imagine a future where the same GET blades used on site today could be recycled, remanufactured, and reinstalled cutting down on emissions, reducing reliance on virgin materials, and making mining operations more sustainable.

As a supplier of grader blades, we’re watching these developments closely. More recycled steel in mining wear parts could be a win-win—helping fleets meet sustainability targets while still delivering the durability needed on-site.

The other benefits of an electric arc furnace in steelmaking include:

- Lower initial costs

- Takes up less space

- Faster manufacturing time (if recycling material can be efficiently supplied)

Is it time we really started driving change in our industry for the better of the environment and to support our mining customers as the push to make operations more sustainable?