Top 10 tips for improving dozer GET life

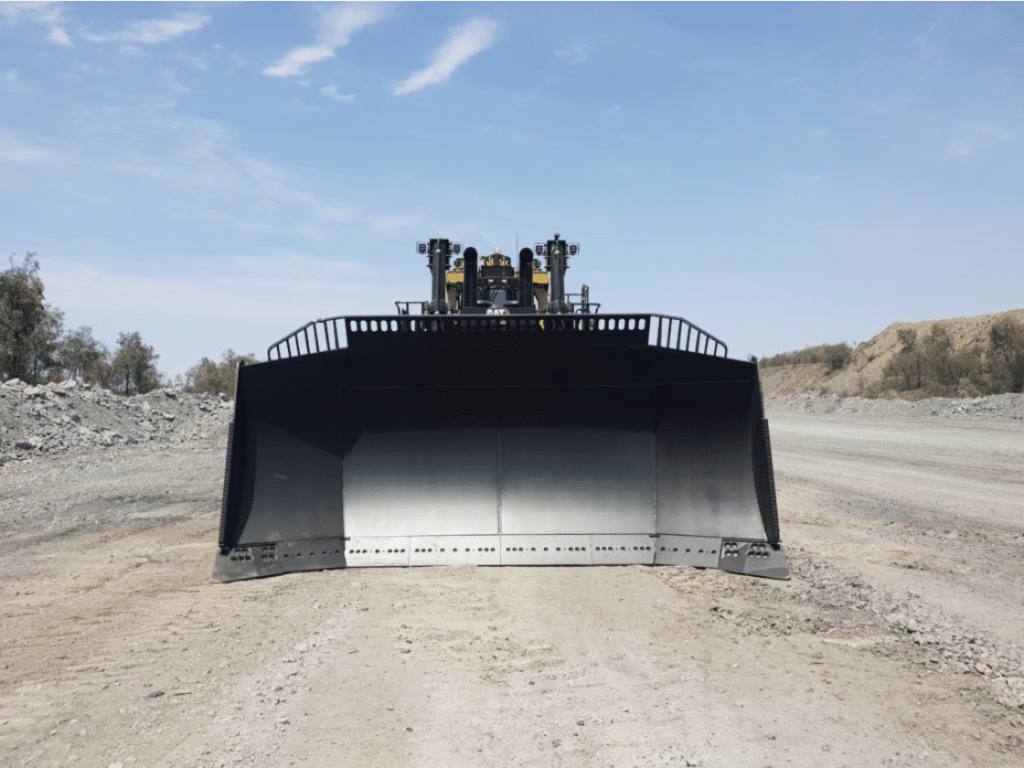

Dozer GET might be out of sight, but it shouldn’t be out of mind. In high-production mining environments, cutting edges, end bits, and ripper boots take a daily beating. But with the right inspection routines, operator habits, and product selection, you can significantly extend their life and cut back on downtime, changeouts, and unnecessary spend.

This article outlines 10 practical, field-tested tips to help mining operations get the most from their dozer GET, reduce $/hour operating costs, and improve machine uptime across the fleet.

Top 10 tips for improving Grader GET life

1 – Watch Grader Speed Avoid high speeds which accelerate wear andreduce control. For haul road maintenance theideal speed is between 5-16km/h. Neverexceed 16km/h and aim for around 10km/h forbest results. Excessive speed when operating a motor grader can lead to several issues, including bouncing, damaged surfaces, increased fuel consumption, and operator fatigue. 2 – […]

TOP 5 GRADER GET WEAR MANAGEMENT STRATEGIES IN 2025

INTRODUCTION – WHAT IS ACCEPTABLE WEAR? If you talk to any maintenance professional (planner, superintendent etc.) about the wear management of ground engaging tools (GET) one thing is clear. Everyone has a different benchmark for what constitutes acceptable wear. This isn’t surprising when you think of the dramatic variances that occur at different mine sites […]

The State of the Australian Mining Industry in 2025

Industry Overview As we progress through 2025, Australia’s mining sector remains a pivotal contributor to the national economy, accounting for approximately 15% of the country’s GDP and providing employment to over 1.1 million individuals. This includes 300,000 jobs within the Mining Equipment, Technology, and Services (METS) sector. Despite its significance, the industry faces a multifaceted […]

Is it time we looked at more recycled steel for mining wear parts?

The mining industry is under increasing pressure to decarbonise, and one of the biggest levers we can pull is the materials we use, starting with steel. Right now, grader blades and other GET (ground engaging tools) are primarily made from virgin steel, but what if manufacturers could shift to using more recycled content? Steel production […]

Mining Expos – Worth the Time and Money? ⏳ 💸

A short blog about the upcoming mining expos that Plasma Wear Parts are attending.

Why would any mine site choose a small business mining supplier over an OEM?

If you’ve ever worked in a small business that supplies the mining industry it’s almost certain you’ve been asked this question. This is not said with any malice as it’s a legitimate question that you must address. If you were working for a mining company, you would be thinking this and it’s a more than […]

CASE STUDY – VBL TUNGSTEN TOUGH GRADER BLADES

PROJECT CAT 24 GRADER BLADES CLIENT MAJOR NSW COAL MINE OVERVIEW Our client was looking for cost improvements across a fleet of 4 CAT 24 graders. They had already made improvements by applying160mm high hardfacing to a heavy duty60mm blade but were interested in seeing if there were any options to increase the wear hours […]

Maximising grader performance with the right Ground Engaging Tools (GET)

When it comes to maintaining haul roads, or fine-tuning surfaces, a grader is only as effective as the ground engaging tools (GET) it’s equipped with. The right GET selection and maintenance can significantly impact productivity, efficiency, and operating costs. In this article, we’ll explore the best practices for maintaining grader GET, the benefits of serrated […]