PROJECT

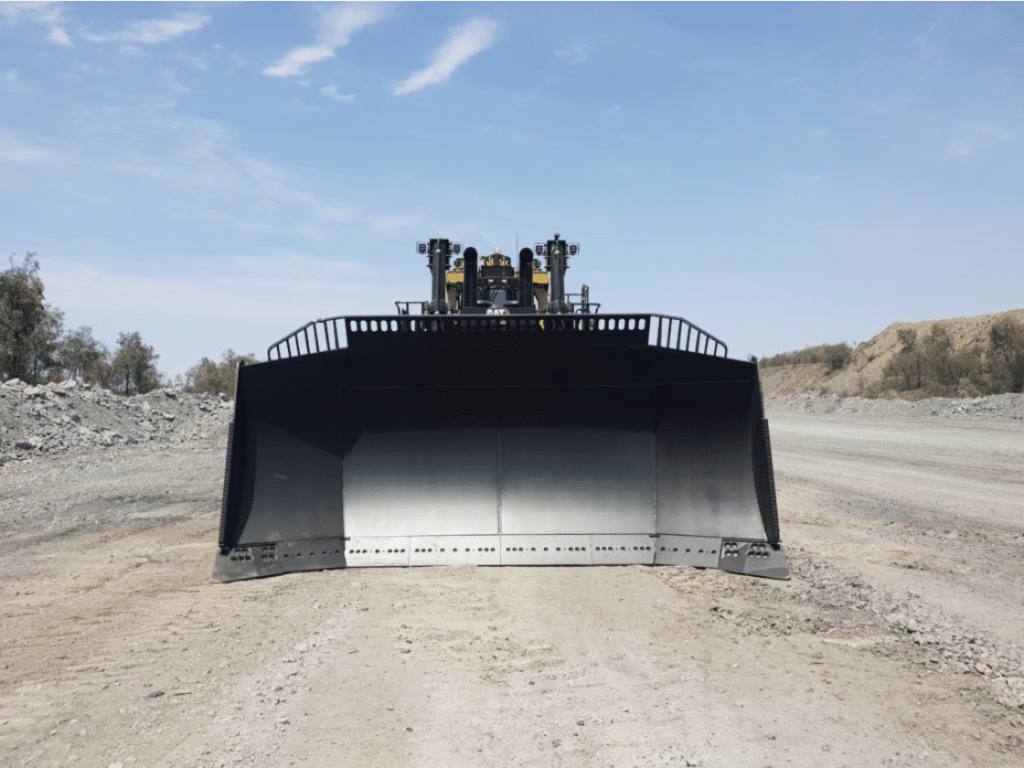

CAT 24 GRADER BLADES

CLIENT

MAJOR NSW COAL MINE

OVERVIEW

Our client was looking for cost improvements across a fleet of 4 CAT 24 graders. They had already made improvements by applying160mm high hardfacing to a heavy duty60mm blade but were interested in seeing if there were any options to increase the wear hours further.

Based on trials conducted in South America, Valley Blades Ltd (VBL) had already seen success with their Tungsten Tough product which had achieved double the life of standard hardfaced blades. Our client were happy to trial the product and see if they could reduce current orders by half.

KEY ISSUES

The client was also interested in reducing the number of changeovers to provide a safer environment for workers with less high risk changeovers required. This would free up maintenance staff’s time, improve team morale and reduce exposure to injury.

Another key goal was to reduce steel waste. With a blade weight which went from 220kg to only 92kg and half the changeovers per annum the carbon footprint would be lowered significantly.

SOLUTION

The customer engaged PWP to propose the ideal design for the Tungsten Tough grader blades. The blades were run on the hardest working CAT 24 grader and compared to the hours achieved on the previous set on the same machine and historically over a 12-month period.

The comparison revealed a significant improvement of 1305 hours exceeding the12-month benchmark average of 750 hours.

The wear life achieved a 74% increase in wear life and amazingly 76% less steel waste. With less changeovers it also freed up 32 hours of staff time lost on changeovers per annum.

BENEFITS

COST SAVINGS

- By sourcing parts from PWP and utilising the Tungsten Tough product the client saved in excess of $100k per annum.

REDUCED CHANGEOVERS

- With nearly half the number of changeovers required staff are less exposed to risk and can use time for other tasks.

LOWER CARBON FOOTPRINT

- 76% less steel is required due to lighter, smaller and longer wearing grader blades.

THE RESULT

- 74% Longer lifespan compared to OEM

- $140,766 in annual savings on fleet GET costs

- 76% reduction in annual steel waste

Want to learn more?

Call us on 0450 372 229

Email – sales@plasmawearparts.com.au