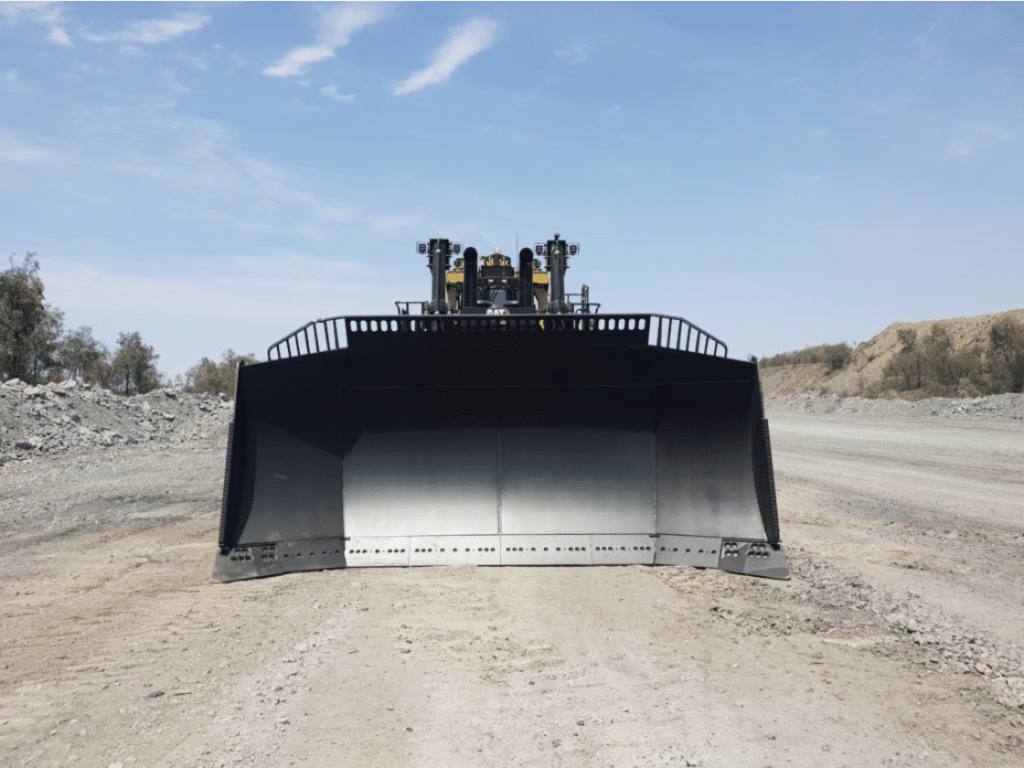

When it comes to maintaining haul roads, or fine-tuning surfaces, a grader is only as effective as the ground engaging tools (GET) it’s equipped with. The right GET selection and maintenance can significantly impact productivity, efficiency, and operating costs. In this article, we’ll explore the best practices for maintaining grader GET, the benefits of serrated edges for better penetration, and tips for improving wear life.

The Importance of Proper GET Maintenance

Graders operate in harsh environments where cutting edges, end bits, and overlays face constant abrasion and impact. Proper maintenance ensures optimal performance and extends the lifespan of these components. Here are some key maintenance tips:

- Regular Inspections – Inspect cutting edges and end bits daily for excessive wear, cracks, or uneven wear patterns. Catching issues early prevents more costly repairs and downtime.

- Rotation and Flipping – To maximise wear life, periodically rotate and flip cutting edges or bits before they become excessively worn. This ensures even usage and delays replacement costs.

- Tighten Bolts Regularly – Loose bolts can lead to edge movement, causing premature wear and reducing cutting efficiency. Check and tighten all fasteners as part of routine maintenance. For long wear grader blades Plasma Wear Parts recommends Nord Lock dual washers.

- Keep Surfaces Clean – Mud, debris, and buildup can cause additional wear and reduce the efficiency of cutting edges. Regular cleaning prevents unnecessary stress on the components.

- Monitor Blade Angles – Operating at the correct blade angle minimizes stress on the GET, improving both grading performance and longevity.

Serrated Edges: Better Penetration for Tough Conditions

Serrated cutting edges are becoming increasingly popular for graders, particularly in compacted or frozen materials. These edges offer several advantages:

- Enhanced Penetration – The notched design allows for improved cutting action, making it easier to break through hard or compacted surfaces.

- Reduced Load on the Machine – By slicing through material more efficiently, serrated edges lower the effort required from the grader, reducing fuel consumption and wear on other components.

- Extended Wear Life – The alternating high and low points distribute wear more evenly across the edge, delaying full replacement.

For operators working in varying conditions, serrated edges can be an excellent choice to improve performance and reduce overall costs.

Tips for Extending GET Wear Life

Maximizing the lifespan of your grader’s GET not only lowers operating costs but also enhances job site productivity. Here’s how to get the most out of your cutting edges:

- Use the Right Material – Carbide-reinforced edges last significantly longer than standard steel, especially in abrasive conditions.

- Match GET to the Application – Consider whether straight, serrated, curved or overlay/carbide insert edges best suit your typical job site conditions.

- Implement Proper Operator Techniques – Skilled operators who avoid excessive down pressure and unnecessary blade contact with hard surfaces can greatly extend GET life.

- Store GET Properly – Keeping spare edges in a dry, organised area prevents rust and deterioration before installation. All grader edges should be sent with a protective wrapping to assist site storage.

- Work with a Trusted Supplier – High-quality GET from a reputable supplier like Plasma Wear Parts ensures durability and reliability.

Conclusion

Graders play a critical role in earthmoving, roadwork, and site preparation, and having the right ground engaging tools makes all the difference. Regular maintenance, strategic use of serrated edges, and proactive wear-life strategies can significantly enhance machine performance and reduce costs. For high-quality grader GET solutions, Plasma Wear Parts offers industry-leading cutting edges and end bits designed for maximum durability and efficiency.

Looking to upgrade your grader’s GET? Contact Plasma Wear Parts today to find the best solution for your equipment.