Proper maintenance is crucial for extending the lifespan of your earthmoving equipment, ensuring that it operates efficiently and safely. Here are the top 10 maintenance tips to help you keep your equipment in top shape:

1. Comprehensive & Regular staff training

Comprehensive and regular staff training for earthmoving operators and technicians is essential for several reasons:

- Safety: Safety is a top priority in any industry, but it is particularly critical in earthmoving operations. Heavy equipment and machinery used in construction, mining, and other earthmoving tasks can be dangerous if not operated correctly. Proper training ensures that operators and technicians understand safety protocols, reducing the risk of accidents and injuries.

- Equipment Efficiency: Well-trained staff can operate earthmoving equipment more efficiently. This can lead to increased productivity, reduced downtime, and cost savings. Skilled operators can maximize the performance of the machinery, resulting in better project outcomes.

- Preventing Equipment Damage: Inexperienced operators can inadvertently damage expensive earthmoving equipment. Proper training teaches operators how to handle machinery carefully, reducing the risk of costly repairs and equipment downtime.

- Compliance with Regulations: Many countries and regions have strict regulations governing the operation of heavy machinery, including earthmoving equipment. Training programs ensure that staff are aware of and compliant with these regulations, helping to avoid legal issues and fines.

- Environmental Considerations: Earthmoving activities can have significant environmental impacts. Training programs often include guidance on minimizing these impacts, such as soil erosion control, proper waste disposal, and fuel efficiency. Compliance with environmental regulations is also crucial.

- Skill Development: Regular training allows operators and technicians to continually develop their skills. They can learn about new technologies, tools, and techniques, which can lead to increased job satisfaction and career advancement.

- Reduced Equipment Wear and Tear: Skilled operators are less likely to subject equipment to harsh or improper use, which can lead to less wear and tear. This, in turn, extends the lifespan of the machinery and reduces maintenance costs.

- Improved Communication and Teamwork: Training programs can foster effective communication and teamwork among staff. When everyone is on the same page regarding safety procedures, equipment operation, and project objectives, it leads to better collaboration and project outcomes.

- Adaptation to New Technology: Earthmoving equipment is becoming increasingly sophisticated, with integrated technology and automation features. Regular training helps staff adapt to these technological advancements, ensuring that they can operate and maintain the latest machinery effectively.

- Liability Mitigation: Adequate training can mitigate legal and financial liabilities for the company. In the event of an accident or equipment-related issue, having documented training records can demonstrate the company’s commitment to safety and compliance.

Comprehensive and regular staff training for earthmoving operators and technicians is vital for ensuring safety, operational efficiency, and compliance with regulations. It also contributes to cost savings, environmental responsibility, and staff skill development, all of which are crucial for the success and sustainability of earthmoving operations.

2. Use Quality Equipment

Investing in quality earthmoving equipment may require a higher initial expenditure, but it pays off in the long run by increasing equipment lifespan, reducing maintenance costs, improving performance, and ultimately contributing to the success of your business. The key areas it can impact your business are:

- Durability: High-quality earthmoving equipment is typically built with better materials and construction methods. This durability allows the equipment to withstand the wear and tear associated with heavy-duty tasks in the construction and excavation industries. Cheaper, low-quality equipment may break down or wear out more quickly, leading to frequent repairs and replacements.

- Reliability: Quality equipment is less likely to experience unexpected breakdowns and failures. This reliability minimizes downtime and ensures that your projects can continue without costly delays. In contrast, unreliable equipment can result in lost productivity and revenue.

- Improved Performance: Quality equipment is designed to perform at its best, providing greater efficiency and productivity. The design and engineering of such equipment allow for smoother operation, higher precision, and better control. As a result, you can complete tasks more efficiently, saving both time and resources.

- Reduced Maintenance Costs: High-quality earthmoving equipment tends to require less frequent maintenance and repairs compared to cheaper alternatives. This not only saves money but also reduces the time and effort spent on maintenance tasks, which can be a significant benefit for your business.

- Safety: Quality equipment often comes with advanced safety features and technologies. These safety features not only protect your operators and workers but also help prevent damage to the equipment itself. This results in fewer accidents and equipment damage, further extending the lifespan of your equipment.

- Long-Term Cost Savings: While quality earthmoving equipment may have a higher upfront cost, it often provides a better return on investment over the long term. Lower maintenance and repair costs, reduced downtime, and increased productivity all contribute to cost savings in the long run.

- Resale Value: Quality equipment tends to have a higher resale value compared to lower-quality alternatives. When you decide to upgrade or replace your equipment, you can recoup a greater portion of your initial investment by selling high-quality, well-maintained equipment.

- Adaptable to Different Conditions: High-quality earthmoving equipment is often designed to work efficiently in a variety of environmental and site conditions. This adaptability allows you to use the equipment on a wider range of projects, which can extend its useful life and versatility.

3. Daily inspections

Performing daily inspections on earthmoving equipment is crucial for extending the lifespan of the equipment, ensuring its safety, and reducing downtime. Here’s how daily inspections help in this regard:

- Early Detection of Issues: Regular inspections allow operators to identify and address potential problems early, such as leaks, loose bolts, or worn components. Addressing these issues promptly prevents them from developing into more serious, costly, and time-consuming repairs.

- Preventative Maintenance: Daily inspections help ensure that maintenance tasks are carried out as needed. This includes lubrication, fluid checks, filter replacement, and other routine maintenance activities. Preventative maintenance is key to preventing breakdowns and extending the lifespan of equipment.

- Safety: Ensuring the safety of the equipment is essential for both the operators and those working around the machinery. Regular inspections help identify safety hazards, such as damaged or malfunctioning safety features, worn tires, or hydraulic leaks.

- Optimal Performance: When equipment is well-maintained, it operates at peak performance. This means it can complete tasks more efficiently, which can reduce wear and tear over time. This also translates into lower fuel consumption, which can save on operating costs.

- Reduced Downtime: Unplanned downtime due to equipment breakdowns can be costly in terms of lost productivity. Daily inspections help catch potential issues before they cause major disruptions, reducing downtime and keeping projects on schedule.

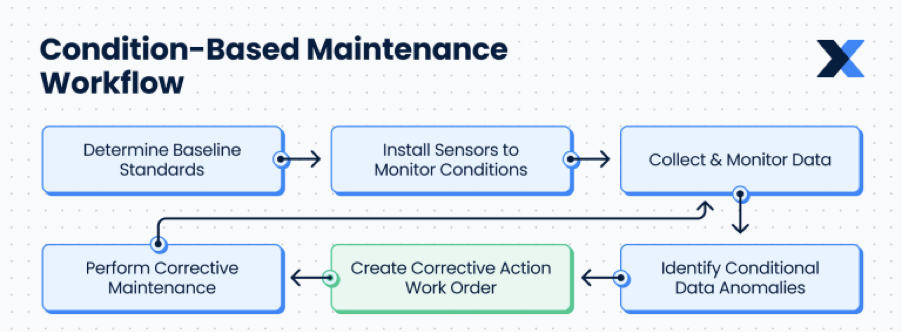

4. Implement a conditions-based maintenance programme

Combined with your regular scheduled maintenance procedures, a condition-based maintenance (CBM) program can help identify signs of wear before they become problematic. The main component of CBM is fluid analysis.

First, you need to determine who will be responsible for these analyses. You have three options here:

- Your staff, if you have the proper materials at hand

- A third-party laboratory

- Your dealer, if they offer this service

It’s vital to perform fluid analysis at regular intervals. You can maximize efficiency by taking fluid samples during standard maintenance procedures, or you can set a specific number of hours to take samples. Every 500 hours is a common interval, but if the machine is a little older, you might want to check it more often.

5. Document all maintenance procedures

Documenting maintenance procedures on earthmoving equipment is essential for several important reasons:

- Consistency: Documented procedures provide a standardized and consistent approach to maintenance tasks. This ensures that all maintenance activities are performed in the same way, reducing the likelihood of errors or omissions.

- Training: Proper documentation serves as a valuable training resource for new equipment operators and maintenance personnel. It helps them understand how to perform maintenance tasks correctly, efficiently, and safely.

- Accountability: Documented procedures establish a clear record of maintenance activities, including who performed them and when. This accountability can be crucial for ensuring that maintenance is carried out as scheduled and in compliance with regulations.

- Safety: Clear maintenance procedures outline safety precautions and best practices. This is crucial for minimizing accidents and injuries during maintenance activities.

- Preventative Maintenance: Documented procedures often include maintenance schedules and checklists, making it easier to track and plan for routine maintenance tasks. This helps prevent breakdowns and costly repairs.

- Troubleshooting: Procedures can include troubleshooting guidelines to help diagnose and resolve common issues quickly, reducing downtime and minimising equipment damage.

- Spare Parts Management: Documentation can include information on required spare parts, part numbers, and sources for replacements. This streamlines the process of acquiring and replacing parts when needed.

- Historical Record: Documentation creates a historical record of equipment maintenance. This record can be valuable for tracking the equipment’s service history, assessing its performance, and making informed decisions about repairs, upgrades, or replacements.

- Warranty Requirements: Some equipment manufacturers may require that maintenance is performed according to their documented procedures to maintain warranty coverage. Having these records ensures warranty compliance.

- Performance Optimisation: Documented procedures can include performance optimisation tips and techniques, helping operators and maintenance personnel get the most out of the equipment and improve efficiency.

To create effective maintenance documentation, follow the manufacturer’s recommendations, industry best practices, and relevant safety guidelines. Be sure to keep the documentation up-to-date as equipment or maintenance requirements change. This documentation is an invaluable resource for ensuring the reliability, safety, and longevity of earthmoving equipment.

6. Implement regular scheduled maintenance

Regular scheduled maintenance is essential for extending the life of earthmoving equipment for several important reasons:

- Preventative Maintenance: Scheduled maintenance involves proactive tasks such as changing fluids, inspecting components, and replacing worn parts before they fail. This prevents small issues from escalating into major breakdowns that can significantly damage the equipment.

- Reduced Wear and Tear: Regular maintenance keeps the equipment in optimal operating condition. Well-maintained machines experience less wear and tear during operation, leading to longer lifespans.

- Improved Performance: Proper maintenance ensures that the equipment operates at its best performance levels. This not only extends its life but also enhances productivity and efficiency.

7. Replace parts when needed and don’t wait too long

- Replacing parts when needed and not waiting too long is a fundamental aspect of proactive maintenance and plays a crucial role in improving the lifespan of earthmoving equipment. Here are some key points to emphasize in this regard:

- Timely Replacement: When components or parts show signs of wear, damage, or reduced performance, it’s important to replace them promptly. Delaying replacements can lead to further damage and potentially result in more extensive, expensive repairs.

- Component Lifespan: Understand the expected lifespan of various components in your equipment. This knowledge can help you plan replacements before they reach the end of their service life.

- OEM Parts: Whenever possible, use original equipment manufacturer (OEM) parts for replacements. OEM parts are designed to meet the equipment’s specifications and are more likely to provide a proper fit and performance.

- Prevent Unplanned Downtime: Replacing parts as needed helps prevent unplanned downtime. Unexpected breakdowns can disrupt operations, lead to costly downtime, and impact project schedules.

- Safety Considerations: Some parts, such as safety-critical components, should be replaced as soon as they show signs of wear or damage to ensure the safety of equipment operators and those working nearby.

- Cost-Effective Approach: Replacing parts on time is generally more cost-effective than waiting until they fail. Timely replacements can save money in the long run by preventing more extensive damage and expensive repairs.

8. Use the right equipment for the job

This is sometimes overlooked when evaluating contributing factors to the lifespan of equipment. It may seem obvious to only use equipment as designed but it is an all-too-common issue. Improper use of equipment can have devastating effects on the reliability of your equipment and can affect your business in many ways:

- Reduced Wear and Tear: When you use equipment that is appropriately sized and designed for a specific task, it experiences less wear and tear. Overloading or using equipment beyond its capacity can lead to accelerated wear and damage to components.

- Improved Efficiency: Matching the equipment to the job ensures that it operates at its optimum performance level. This not only extends its life but also improves efficiency and productivity.

- Preventing Damage: Using the wrong equipment for a job can lead to damage and premature component failure. For example, using an excavator for a task better suited for a bulldozer can strain the equipment and result in costly repairs.

- Safety: Using the right equipment is crucial for the safety of operators and those working around the machinery. Inappropriate equipment choices can lead to accidents and injuries.

- Warranty Compliance: Misusing equipment can void warranties, whereas using the right equipment for the job ensures compliance with manufacturer guidelines and can help maintain warranty coverage.

- Preventing Overworking: Using the right equipment prevents overworking and over-stressing the machinery, which can lead to overheating, breakdowns, and reduced overall longevity.

9. Regularly clean the equipment

It’s important to clean your equipment inside and out to remove contaminant buildup. When left unchecked, deposits of dirt and grime can cause your machines to overheat and wear down at a faster rate. Removing caked-on dirt can also reveal small imperfections like scratches and cracks that could become major issues later.

Dedicate time every few hundred hours to thoroughly scrub your machines down. Force dirt from hard-to-reach areas using high-pressure hoses. For more delicate parts like chains and bearings, you’ll need to use specialized techniques. Follow your manufacturer’s directions to properly clean your unit.

10. Store equipment and replacement parts correctly

Proper storage helps prevent damage, deterioration, and ensures that equipment is ready for use when needed. Here are some guidelines for storing equipment and parts effectively:

- Lubrication and Fluids: Apply appropriate lubricants to moving parts and ensure all fluids (such as oil, coolant, and hydraulic fluids) are at the recommended levels. This helps prevent corrosion and deterioration.

- Battery Maintenance: Disconnect or remove the batteries and store them separately. Batteries should be kept in a cool, dry place and occasionally charged to prevent them from losing power or developing issues.

- Protect from the Elements: Store equipment in a covered, sheltered area to protect it from the elements. If a shelter isn’t available, consider using protective covers or tarps to shield the equipment from rain, snow, and direct sunlight.

- Proper Parking: When storing heavy machinery, ensure it’s parked on a level, stable surface to prevent uneven weight distribution and tire damage. If possible, use blocking or stands to take the weight off the tires.

- Secure the Equipment: To prevent unauthorised use or theft, lock or secure the equipment with the appropriate measures, such as immobilizers, locks, or security systems.

- Replacement Parts: Store replacement parts in a clean, dry, and organized space. Label parts clearly to avoid confusion when needed. Keep a record of your parts inventory, including their condition and shelf life.

- Control Humidity: Maintain a controlled environment with controlled humidity levels if possible. High humidity can lead to rust and corrosion, while low humidity can cause drying and cracking of rubber components.

- Regular Inspection: Periodically check stored equipment to ensure it remains in good condition. Lubricate moving parts and address any issues promptly.

- Training: Ensure that your maintenance and storage personnel are well-trained in the proper storage procedures for the specific equipment you have. This knowledge is essential for maintaining the equipment’s condition.

- Documentation: Maintain records of all maintenance and storage activities, including any servicing and inspections carried out during storage. This documentation is essential for tracking equipment condition and planning for its eventual return to service.

Proper storage practices are vital for preserving the condition of your earthmoving equipment and replacement parts. Following these guidelines can help extend the lifespan of your machinery and minimize repair and replacement costs.

By following these maintenance tips and staying proactive in your upkeep, you can extend the lifespan of your earthmoving equipment and reduce long-term operational cost