INTRODUCTION – WHAT IS ACCEPTABLE WEAR?

If you talk to any maintenance professional (planner, superintendent etc.) about the wear management of ground engaging tools (GET) one thing is clear. Everyone has a different benchmark for what constitutes acceptable wear. This isn’t surprising when you think of the dramatic variances that occur at different mine sites around Australia, the world and even within the same mine pits.

Some maintenance professionals have worked on soft dirt sites where standard blades can last over 2000 hours without issues. Others, however, have cut their teeth in some of the most abrasive pits in Australia where 300 hours is cause for celebration. Not literally but maybe a smile or two.

So, when wear rates shift, whether due to a new mine site, an extension to an existing pit, a change in pit conditions, or unforeseen geology, it can be jarring.

That’s when you need to revisit your strategy.

In this article, we explore the five primary approaches used to combat grader GET wear. Each comes with different sets of pros and cons, but each strategy can benefit your mine site. Let’s break them down.

1 STANDARD GRADER EDGES

The baseline. Commonly used where material is less abrasive and changeout frequency isn’t a major cost factor.

This wear management strategy is usually always the starting point. A lot of graders will be fitted with standard edges from new. It is important to understand what your baseline hours are so you know where you are and where you can potentially go. Once you understand the average hours of a standard blade you can then look at other solutions to reduce your $/h costs.

Best for:

Contractor sites, graders with smaller grader blade sizes, soft materials, or fleet operators prioritising lowest unit cost.

✅ Pros:

· Lower upfront cost

· Fast availability as it is rare suppliers’ stock hardfaced edges as standard

· Suitable for low-abrasion, low wear environments

⚠️ Cons:

· Shorter lifespan

· Increased machine downtime from frequent changeouts

· Higher exposure to risk for staff replacing blades

· Higher cost when compared to other solutions

2 HEAVY DUTY GRADER EDGES – UP TO 60MM

For a lot of mining companies in Australia the approach of bigger is better is a common strategy for wear management. The additional steel mass provides greater defence to delay blade replacement by way of the sheer volume.

Edges are typically 60mm thick though there are options to go as thick as 75mm, but many believe the weight of 75mm thick grader blades places too much extra stress on the grader’s componentry, so few sites go above the heavy duty 60mm thick grader blades. As the thickness increases so too does the width (330mm up to 406mm wide) and as a result the weight can reach more than 200kg per blade.

✅ Pros:

· Improved wear life via greater blade mass

· Low complexity solution

· Common inventory item with high availability from multiple suppliers

⚠️ Cons:

· Added weight can increase stress on componentry

· Higher carbon footprint due to higher volume of steel

· Not best solution for higher wear environments

Best for:

Operators wanting better wear life without looking at hardfacing or premium grader blade solutions.

3 CAST GRADER EDGES

In my experience cast grader blades are not a common option but in certain environments they can be utilised. Cast blades have a different material make up and are typically made of a premium alloy steel with high carbon content. The key difference is that the steel is formed into its final shape by pouring molten steel into molds.

Less suppliers offer cast grader blade options. Of the suppliers that do supply this option they claim that cast blades offer improved durability and wear resistance than rolled steel blades. What is unclear is whether cast blades offer improvements over heat-treated hardfaced grader blades which tend to be the standard in the industry.

✅ Pros:

· Claims of improved wear life over rolled steel options

· Low complexity solution

⚠️ Cons:

· Limited supplier options

· Unclear whether this is a superior solution to other options

· High-cost item only suitable for high wear, high impact environment

Best for:

High wear, high impact environments or sites that are willing to test the wear life against existing GET solutions.

4 HARDFACED HEAVY-DUTY GRADER EDGES

For operators looking to increase their wear hours this is a very common solution. In essence a welding overlay is applied to the grader blades to create a sacrificial coating that protects the steel from wear. The applied hardfacing coating provides a protective barrier for the grader blades.

The key with hardfacing any grader blade is to find the right balance between wear reduction and cost. If you apply more hardfacing than needed, you will increase the cost without increasing the wear life.

✅ Pros:

· Significantly improved wear resistance

· Proven solution for mid-to-high abrasion environments

· Reduces changeovers and exposure to high-risk activities

⚠️ Cons:

· Higher procurement costs than standard blades

· Can increase lead time if not supplied as standard to site

· Requires high quality welding with proven wear patterns

Best for:

Sites transitioning from standard blades to extended wear life with minimal change to install practices.

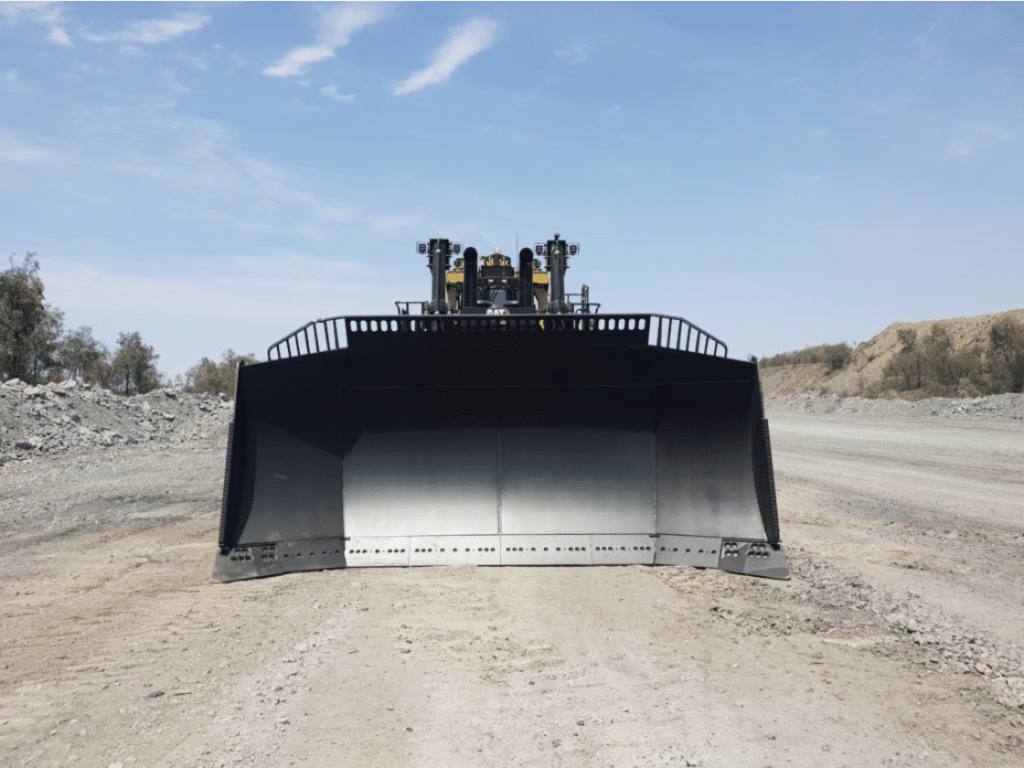

5 EXTREME WEAR SOLUTIONS

For the more adventurous and sites with higher wear environments there are solutions that can greatly increase your wear life even beyond traditional hardfacing solutions. This is the world of extreme wear solutions.

Plasma Wear Parts in partnership with Valley Blades Ltd in Canada offer two such solutions that are now available in Australia. TUNGSTEN TOUGH™ which combines the use of embedded tungsten chip overlays with carbide inserts to dramatically increase grader wear life. For sites running serrated blades there is also a new product called XTREME GRADE™ which utilising heavy duty boards fitted with wear plates and finished with 35mm rotational bits than can be replaced as and when needed at a fraction of the cost of traditional serrated blades.

✅ Pros:

· Up to 100% lifespan improvement over hardfaced edges

· Reduced changeouts

· Improved $/h costs

· Lower carbon footprint due to reduce blade weight and quantity required

⚠️ Cons:

· Higher upfront costs

· Must match application carefully to avoid overkill

Best for:

Hard rock operations, road construction within mining sites, and anyone pushing their grader wear life to new levels.

SO WHICH STRATEGY IS BEST?

The real answer is it depends.

Your ideal wear solution isn’t about chasing the longest hours at any cost. It’s about balancing wear resistance with operational efficiency, safety, machine capability, and total cost of ownership.

At Plasma Wear Parts, we take a consultative approach. We ask questions. We analyse site conditions. We consider your operators, not just your budget.

If your current wear strategy isn’t cutting it, or if your site conditions are shifting, we’re here to help you pivot.

Get in touch for an on-site assessment or to explore wear trial options.

Email – sales@plasmawearparts.com.au

Plasma Wear Parts – Working with Australia’s best mine sites by supplying Australian’s toughest mining blades.