If you’ve ever worked in a small business that supplies the mining industry it’s almost certain you’ve been asked this question. This is not said with any malice as it’s a legitimate question that you must address. If you were working for a mining company, you would be thinking this and it’s a more than fair question to ask a potential supplier.

When I started Plasma Wear Parts back in 2012, we really didn’t have a good answer to this question. We were unproven, we didn’t have a clear strategy, and we didn’t yet have the experience to be a legitimate option. But we were ambitious, passionate and eager to learn.

Even now, more than 12 years on I still get asked this question. It can be unnerving but as a smaller operator you have to embrace your advantages and thankfully smaller players do have some distinct points of difference to our more illustrious competitors.

Lean into your strengths

It can be a bit like David v Goliath but there are several advantages that a smaller supplier can utilise to even up the playing field. The first thing is to find a product offering that changes the game. If you offer something that is 5 or 10% better it just won’t move the needle enough to gain traction. You need to be significantly better than what is already out there in the market. We are talking about a 50-100% improvement. This isn’t easy to find but you need to remember that changing suppliers is an arduous and risky task for a mining company so the payoff needs to be massive for them to be interested in making the change.

Don’t tell me it’s better; show me it’s better!

As Public Enemy once said, “don’t believe the hype…”. Nobody likes to be sold to and words mean nothing without concrete evidence. Every claim you make needs to be backed up with real world data and social proof. This means you need to embrace the field trial and ensure that the best outcome is achieved for both parties. The key is to set the expectations from the outset with benchmarking. It requires open communication and true collaboration with the customer from the outset. The mine site needs to say what a successful trial is in their eyes, and you need to be honest about what you can deliver. It is a journey and will require time and patience from both sides but when done right provides it can achieve truly outstanding results.

What makes a successful trial?

There are several keys to a successful trial but in short the minimum requirements are:

- No free trials (no money equals no customer buy-in)

- Understanding of the current state of play (without a starting point how will you know what the destination is?)

- Information sharing (data must be tracked accurately and shared in a timely manner)

- Regular site visits (you must visit the site and monitor the product, take pictures, talk to operators, key customer contacts to get a feel for how it is going on the ground)

- Collaboration – when the customer and supplier work in unison the results are exceptional

- Reporting – at the end of the trial can you present the findings in a way that resonates with the customer and makes it easy for them to get approval to change suppliers?

Do you solve problems and address the right pain points for the customer?

In the early days we tried to solve as many problems as we could. However many of our solutions did not address genuine pain points for the customer. We thought any cost saving was what the customer wanted to solve but that was naïve and incorrect. If you offer a customer a smorgasbord of solutions and options, you end up looking like a snake oil salesman and this is extremely off putting. You need to ask insightful questions to get to the heart of what is important to them. If your offering does not fix their main pain points, you are wasting everyone’s time and are better to walk away.

Specialising makes you special

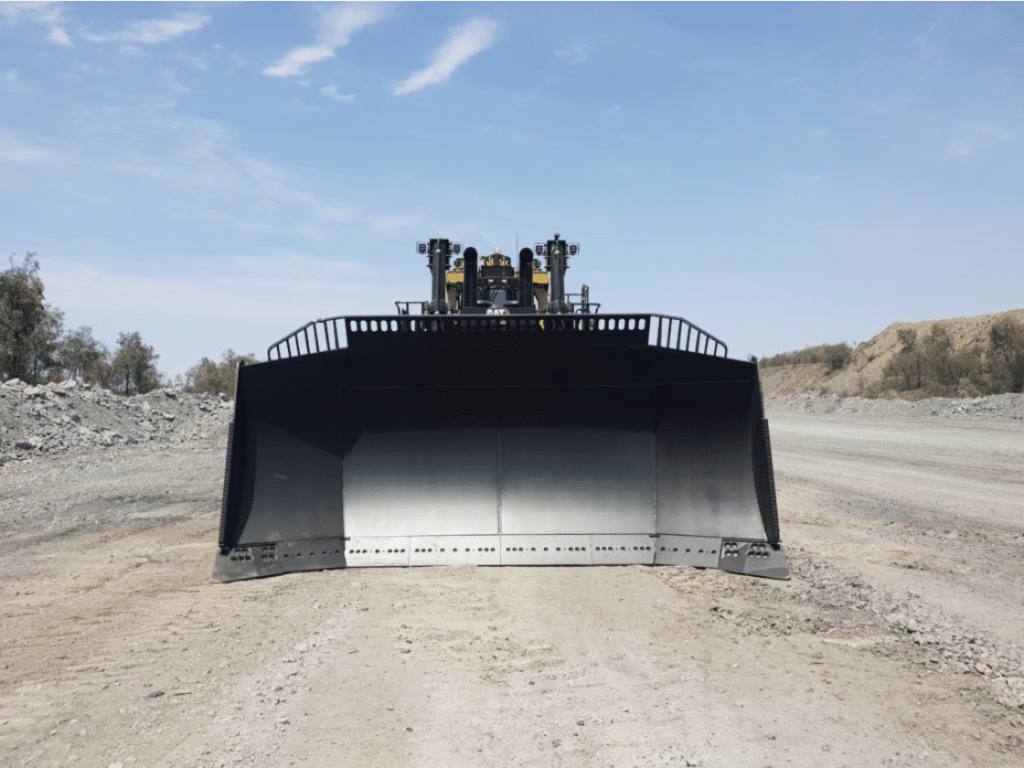

The turning point for our business came when we stopped trying to supply every product we could and concentrated on products where we could see a gap in the market and could add a real point of difference. Finding a niche and being a specialist of a small product range is the best way to stand out from every other supplier. We went from a carpet-bombing approach to offering a limited range of products for one machine. This meant we only had 3 products to offer which makes it easier for the customer to digest and made us a standalone specialist in the market. This is a blue ocean marketing strategy where you create your own sub market and look to dominate with limited competition.

Partnering with the best

You can’t get there on your own. No matter how good your business is you need help. We had worked with other competitors both large and small in Australia but we knew we needed a large, proven market leader that was not a direct competitor. That company was Valley Blades Ltd who had a wealth of experience (founded in 1962) but was not active in the Australian market and based in Canada. Once we saw how they were focused on innovative products that outperformed the current market offerings it was a seamless transition to start promoting and distributing their products. With additional marketing support and innovative products we knew we had a point of difference in a competitive market.

Putting it all together

Once you have a great product offering, a laser focused product range you need to start proving you are an authority in your field. This takes time and is a continual process. Larger OEM suppliers are experts in their field but with a huge product range the focus tends to be on the higher cost items or on the industry as a whole. This means a specialist supplier can focus on a limited range of products and add real value for the customer. The other benefit is that if you only offer a small range of products, you can really gain a deep understanding with laser focus. It is much easier to be an expert of one product than for a range of products.

So why would you choose a small company over an OEM?

If I were to answer that question know I would say for the following reasons:

- Cost savings – a lean operation can pass those savings directly onto the customer

- Customised offering – we work with you to find the best one-off solution to meet your needs

- Streamlined real time supply – By partnering with a nationwide 3PL solution provider and only selling your stock to you we can ensure no supply issues or delays in shipments

- Relentless innovation – We only provide 2 products and we work with one of the world’s most innovative GET suppliers. We are only interested in selling the best version of these products that delivers huge savings, lowers changeovers, machine downtime which means best $/h return for our customers.

How do you compete with your respective big company competitors in your market?